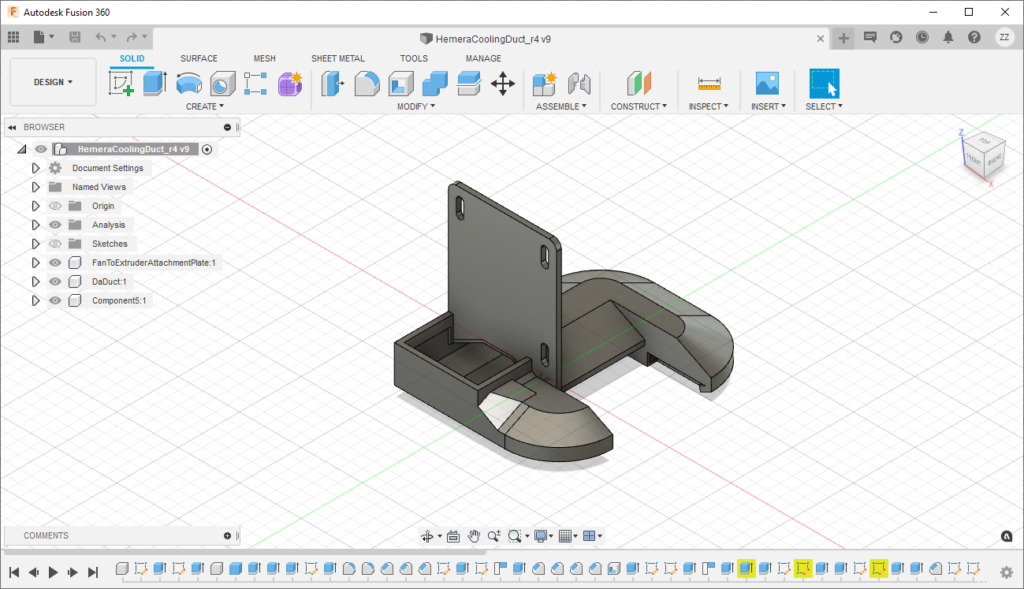

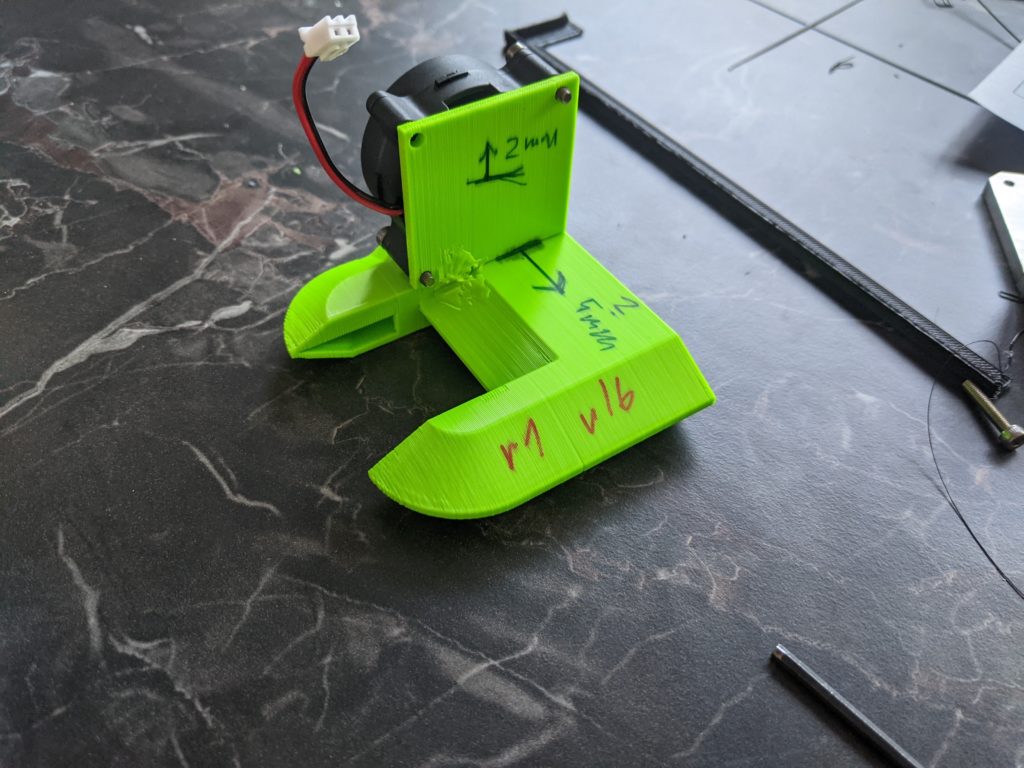

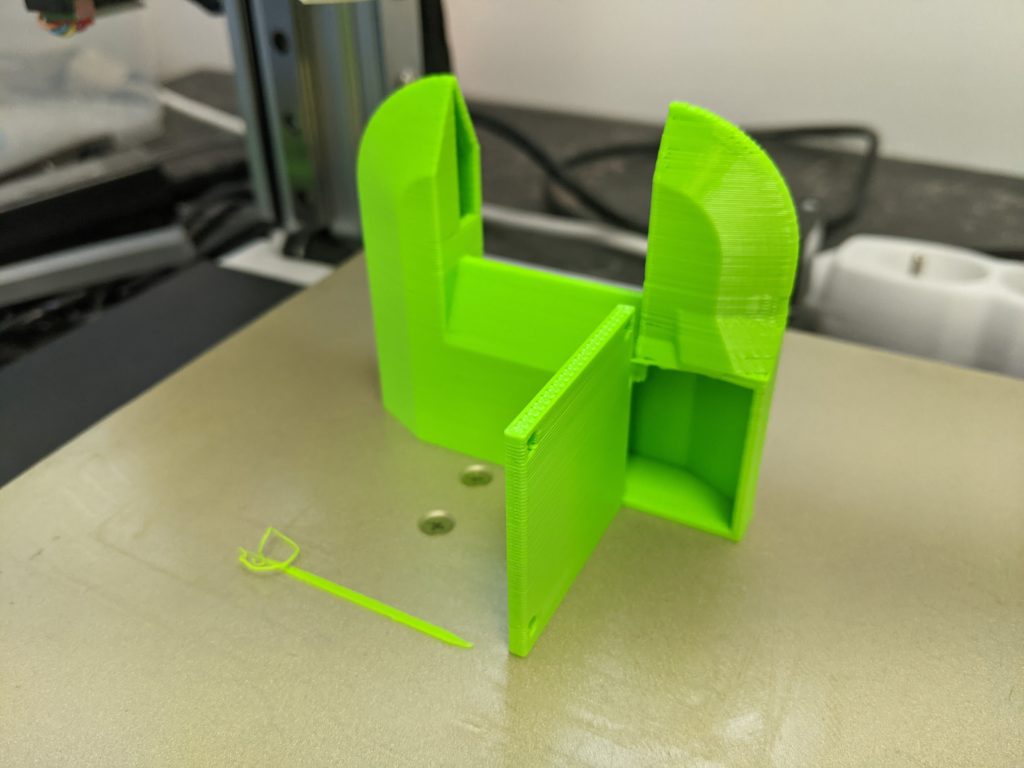

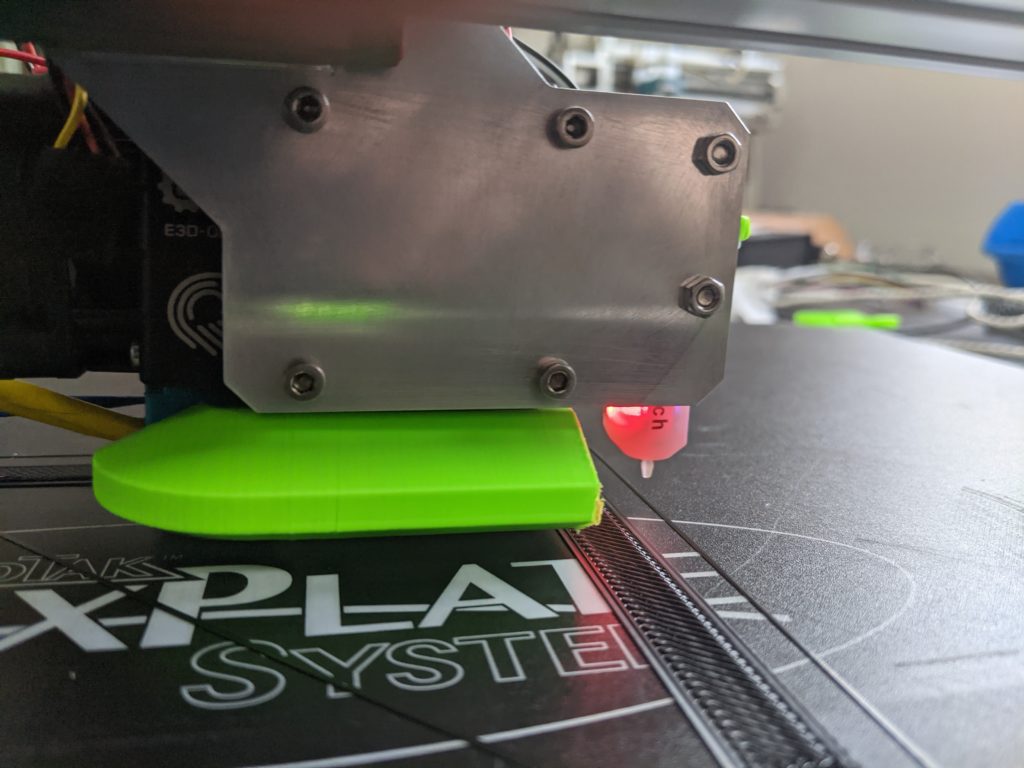

Product cooling air duct

Printed as one hollow part.

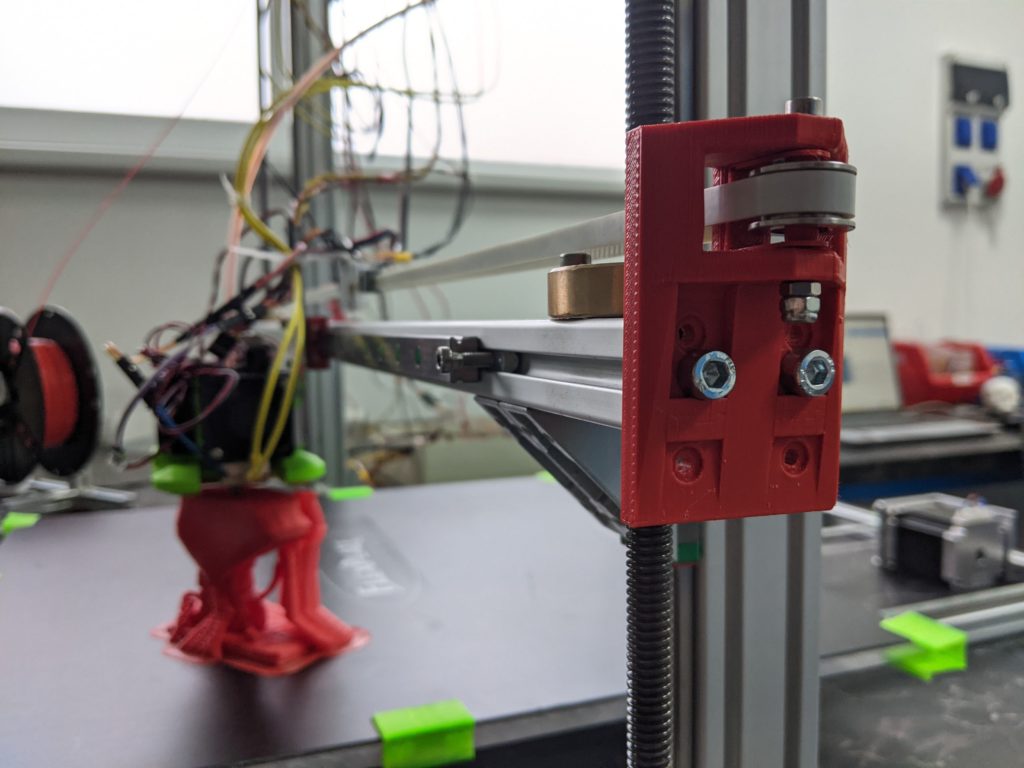

Extruder frame (rail) mount was prototyped from plastic as well. After making sure that everything fits it was manufactured from aluminium alloy at poxon.cz.

Dimensions H, W, D [cm]: 6.5; 8.4; 6.7

Time: 1 h (0.3mm layer)

Material: 22 g, PLA

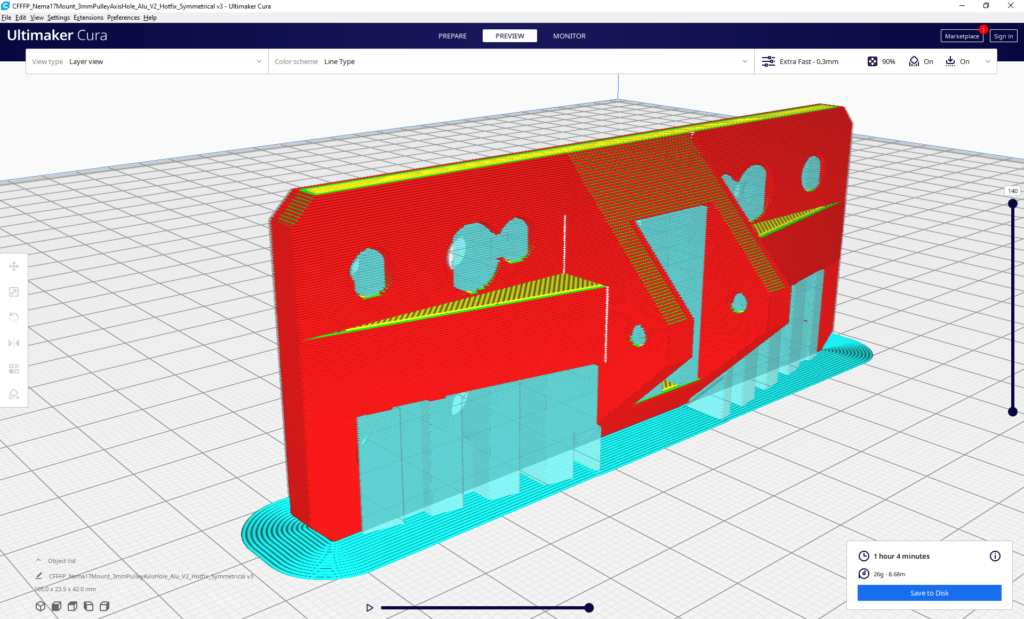

Broken drawer carriage

Design and manufacturing of a new one, stress test preparation.

Dimensions H, W, D [cm]: 5.3; 5.4; 2

Time: 33 min (0.3mm layer)

Material: 15 g, PLA

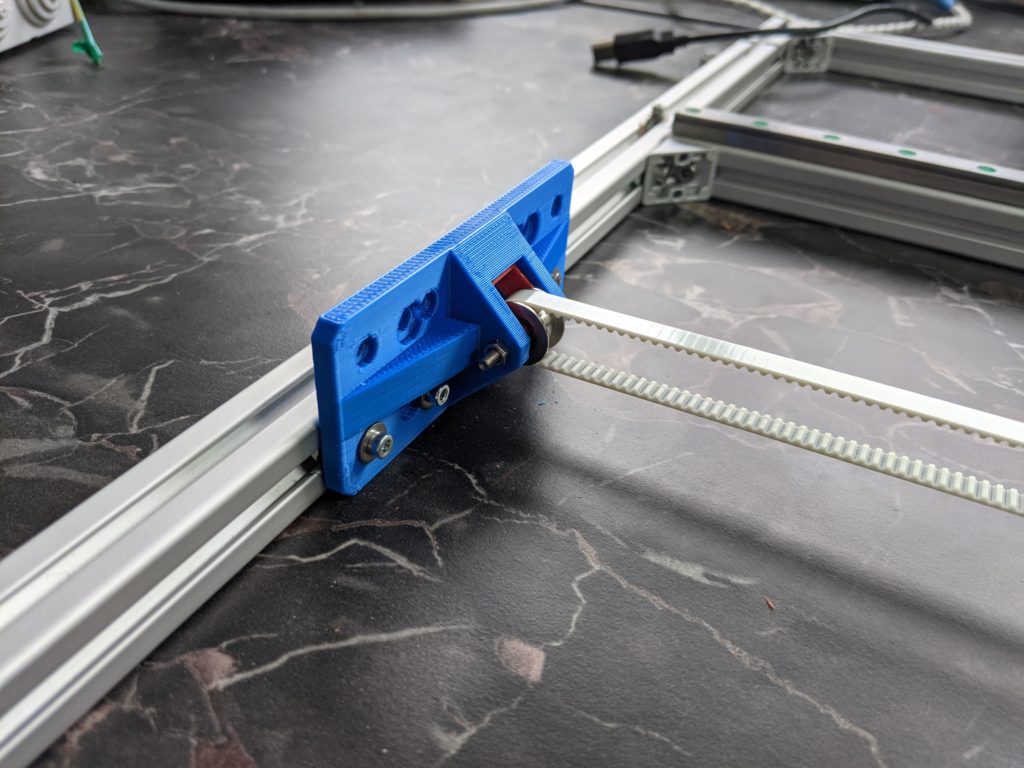

3D printer smooth idling pulley

Design, bearing centering insert (printed separately). The bearing sides are hollow.

Serves as a prototype for future monufacturing out of aluminium allow. Braces in between screws are only present in the plactic version. There are screws at both sides of the blue version in the picture because the forces that are being applied onto the plastic mout kept bending the mount a bit. That could lead to inaccuracy.

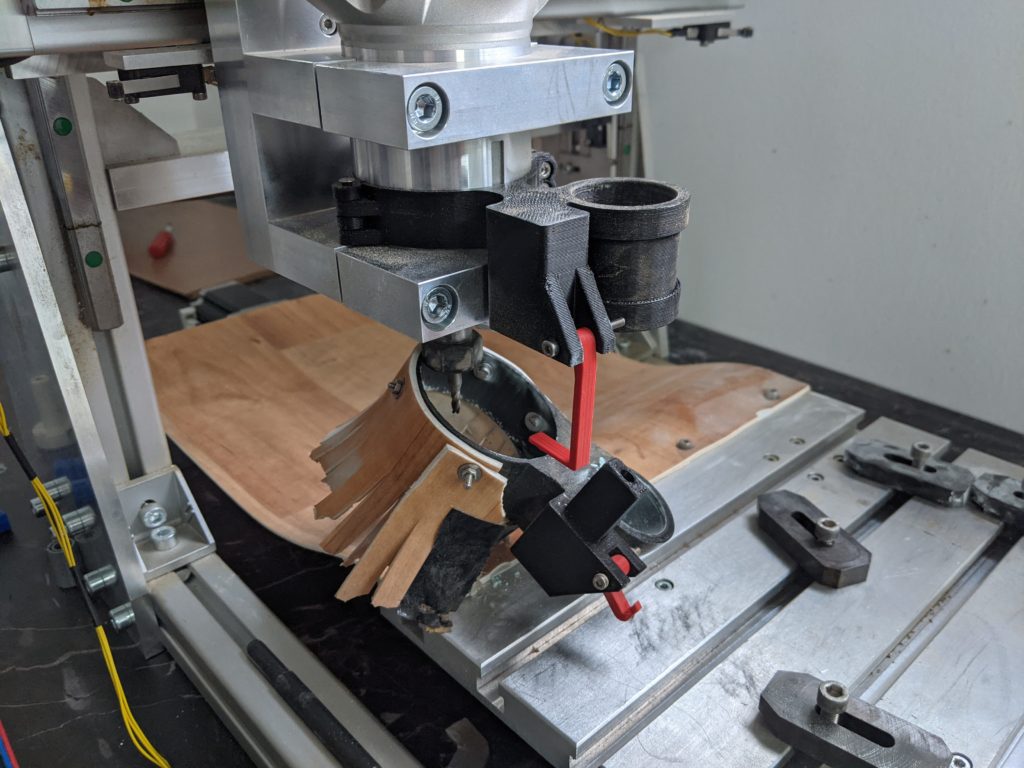

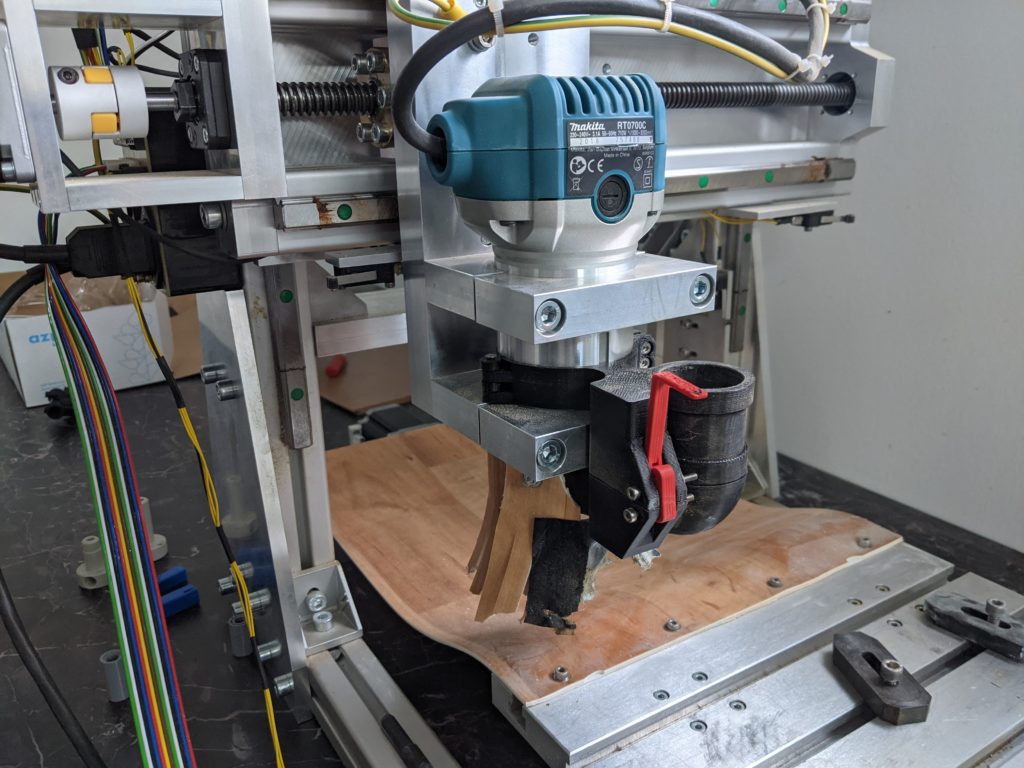

Miller sawdust removal

The vacuum cleaner hose is inserted into the hole in the top part, the milled off material is removed.

The product is intenionally made out of two parts so that the fastened mill drill bit can be changed easily. The axes, the Z zeroing especially, can be set easily as well.

Rack hanger

Fitts into the holes in the rack columns so that it is attached firmly.

Dimensions H, W, D [cm]: 4.5; 4.6; 7.2

Time: 53 min (0.3mm layer)

Material: 17 g, PLA

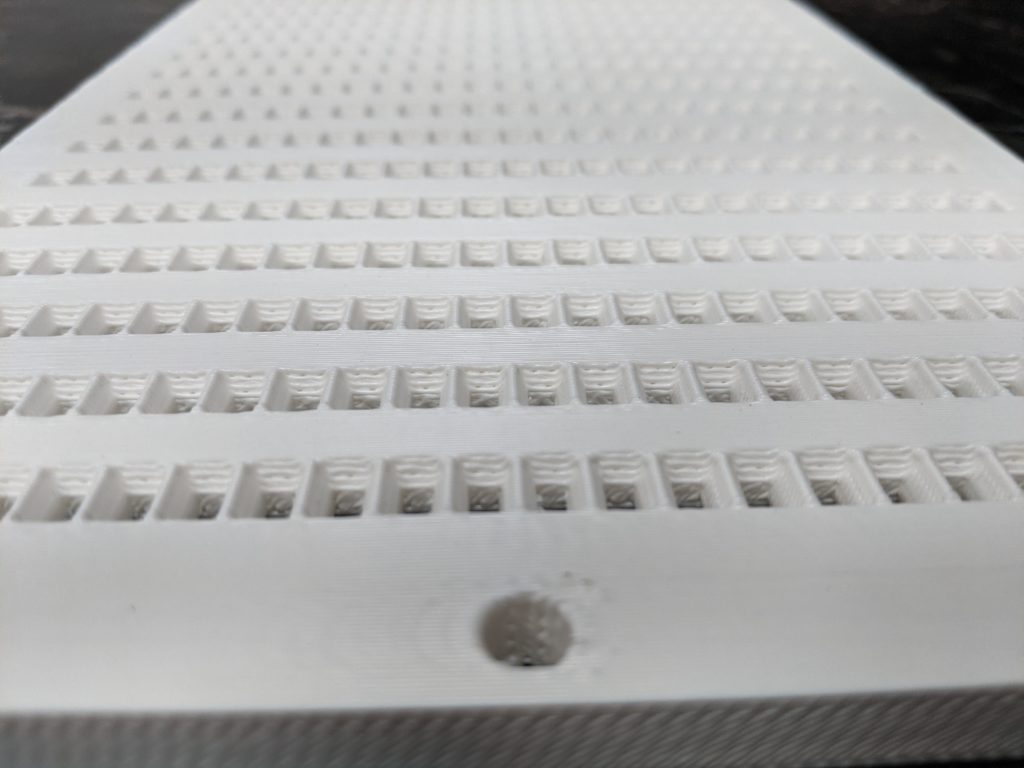

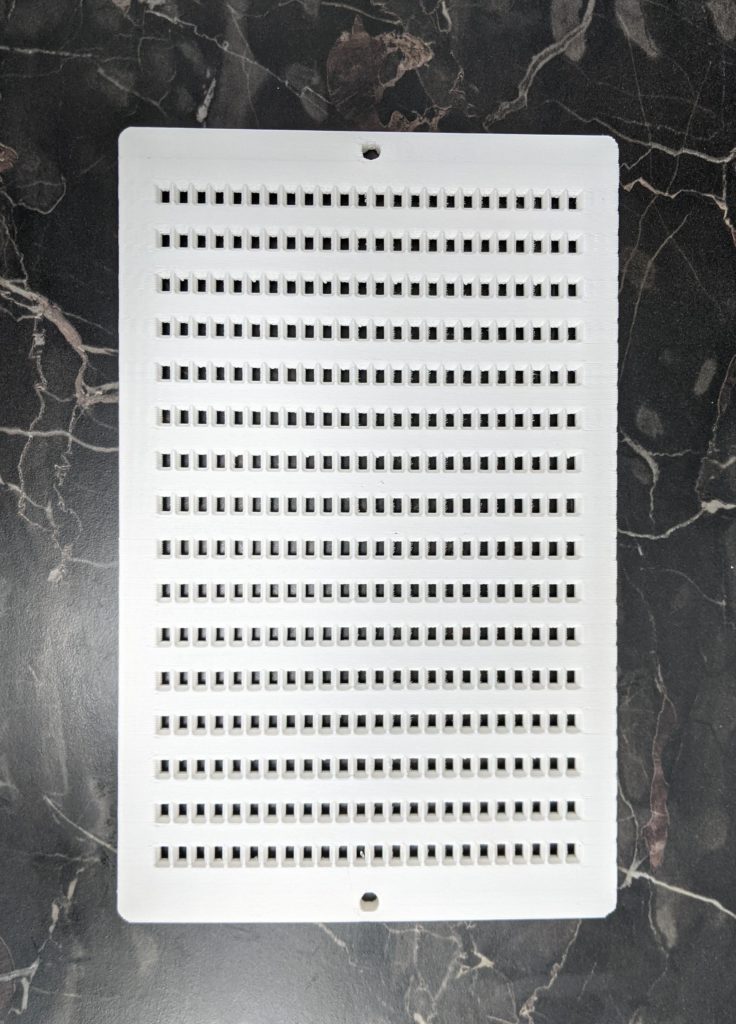

Chip tray

Dimensions H, W, D [cm]: 0.8; 17.7; 27.9

Material: PLA

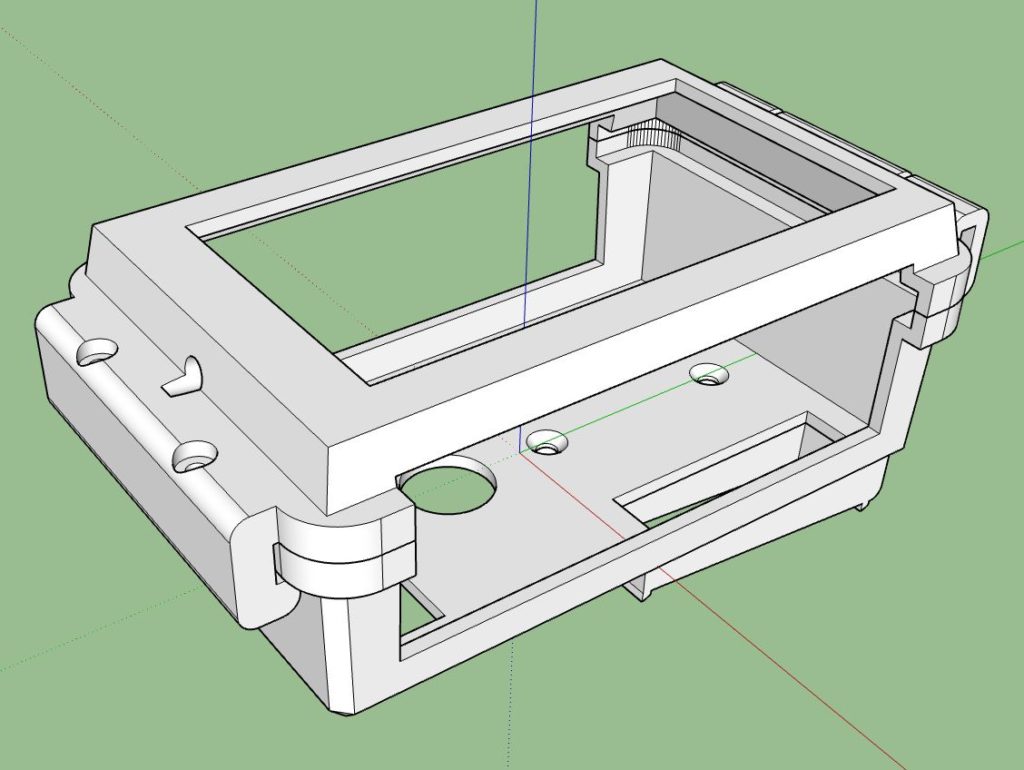

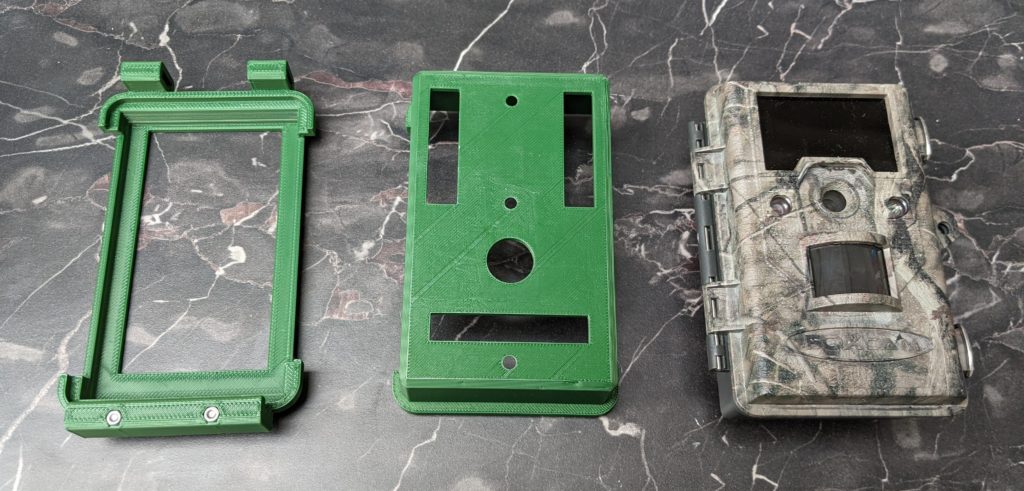

Camera Trap Enclosure

Dimensions H, W, D [cm]: 5.7; 9.5; 16.6

Time: 5 h (0.3mm layer)

Material: 145 g, PLA

Fishing feeding rocket

Payload release mechanism.

Parkside Battery Slot